Unmatched Durability: Discover the Excellence of Marine Grade 5086 H116 Aluminum Plate

In the demanding world of marine engineering, construction, and industrial applications, materials must withstand harsh environments, resist corrosion, and maintain structural integrity over time. Among the myriad of aluminum alloys, Marine Grade 5086 H116 aluminum plate stands out as a superior choice for applications where durability and performance are paramount.

This comprehensive guide explores the features, advantages, applications, and supplier insights related to 5086 H116 aluminum plate, with a special focus on Huawei Aluminum, a leading manufacturer in the industry.

Introduction to Marine Grade Aluminum Alloys

Marine environments expose materials to saltwater, humidity, temperature fluctuations, and mechanical stresses.

Therefore, selecting an appropriate aluminum alloy is critical for longevity, safety, and cost-effectiveness.

Why Aluminum Is the Material of Choice in Marine Applications

- Lightweight yet Strong: Aluminum offers an excellent strength-to-weight ratio, reducing vessel weight and improving fuel efficiency.

- Corrosion Resistance: Marine-grade aluminum alloys contain elements like magnesium, which enhance resistance against saltwater corrosion.

- Machinability and Fabrication: Aluminum alloys are easier to cut, weld, and form, facilitating complex designs and repairs.

- Cost Efficiency: Aluminum reduces overall costs due to lower maintenance and higher durability.

Overview of Marine Grade 5086 Aluminum Alloy

Marine Grade 5086 is recognized worldwide for its exceptional performance in seawater and marine environments.

Composition and Properties

| Element | Content Range (%) | Purpose |

|---|---|---|

| Magnesium | 4.0 – 4.9 | Enhances corrosion resistance and strength |

| Manganese | 0.70 – 1.0 | Offers good corrosion resistance |

| Iron | ≤ 0.40 | Improves alloy strength |

| Silicon | ≤ 0.40 | Stabilizes the alloy during casting |

| Others | Trace elements | Minor influence on properties |

Key Attributes of 5086 H116 Aluminum

- High Strength: H116 temper offers increased strength while maintaining excellent ductility.

- Superior Corrosion Resistance: Especially resistant to saltwater, making it ideal for marine use.

- Good Weldability: Suitable for welding and forming operations.

- Excellent Machinability: Facilitates detailed fabrication and precision manufacturing.

The Significance of H116 Temper in Marine Aluminum

The temper designation H116 indicates strain-hardened and stabilized alloy, optimized for strength and corrosion resistance.

What Does H116 Mean?

- H: Strain-hardened

- 116: Specific hardening condition, indicating partial tempering with a focus on high strength

Benefits of H116 Temper

- Enhanced Mechanical Strength: Suitable for structural components in demanding marine environments.

- Maintained Ductility: Ensures components can absorb shocks and stresses without cracking.

- Predictable Performance: Consistent properties facilitate reliable design and engineering.

Advantages of Marine Grade 5086 H116 Aluminum Plate

The combination of alloy composition and temper condition grants 5086 H116 plates numerous advantages:

1. Outstanding Corrosion Resistance

Marine grade 5086 H116 exhibits superior resistance to saltwater and atmospheric corrosion, significantly extending service life.

2. High Mechanical Strength

Compared to other marine aluminum alloys, 5086 H116 offers a balance of strength and ductility, vital for structural components.

3. Excellent Weldability and Formability

This alloy welds easily using common techniques like TIG and MIG, facilitating complex structures and repairs.

4. Superior Fatigue Resistance

Suitable for dynamic marine environments, the alloy withstands cyclic stresses without fatigue failure.

5. Cost-Effective Durability

Despite its high performance, 5086 H116 provides a cost-effective solution due to lower maintenance and longer lifespan.

6. Good Cold Workability

Remains pliable for shaping and forming, enabling intricate designs and custom applications.

Comparing Marine Grade 5086 H116 with Similar Alloys

While 5086 H116 boasts impressive qualities, understanding how it stacks up against similar alloys helps in making informed choices.

| Feature | 5086 H116 | 5052 H32 | 5083 | 5454 |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Very Good | Good |

| Strength | High | Moderate | Moderate | Moderate |

| Weldability | Excellent | Excellent | Good | Good |

| Formability | Good | Excellent | Good | Good |

Note: 5086 H116 is generally preferred for applications requiring higher strength and saltwater resistance.

Practical Applications of Marine Grade 5086 H116 Aluminum Plate

Due to its robust profile, 5086 H116 aluminum plate finds extensive use across diverse marine and industrial sectors.

Marine Industry

- Shipbuilding

- Boat hulls and decks

- Offshore structures

- Superstructures

Transportation and Vehicles

- Railcars

- Truck trailers

- Railway wagons

Industrial Equipment

- Pressure vessels

- Storage tanks

- Refrigerated containers

Architectural and Structural Uses

- Marine-related architectural features

- Bridge components

Case Study: Marine Vessel Construction

A leading shipbuilding company selected 5086 H116 aluminum plates for constructing the hull due to:

- 30% weight reduction compared to steel

- Superior saltwater corrosion resistance

- Ease of fabrication and welding

The vessel remains operational after 10 years at sea, demonstrating the alloy's durability.

Manufacturing and Processing of 5086 H116 Aluminum Plates

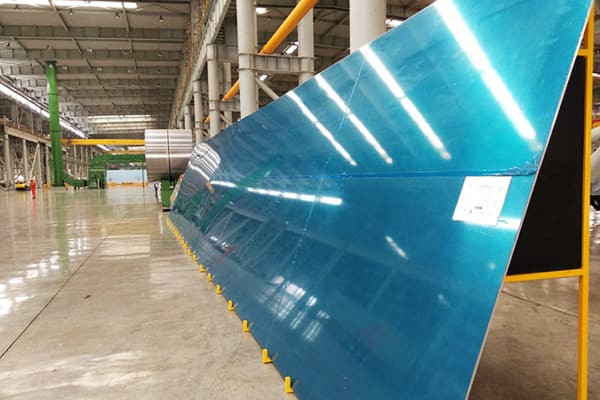

Processing practices influence the performance of the final product. Here is an overview of how Huawei Aluminum manufactures 5086 H116 plates:

Material Selection

- High-quality billets and ingots

- Strict quality control during melting and casting

Rolling Process

- Hot rolling for initial thickness reduction

- Cold rolling for final dimensions and surface finish

- Thermomechanical treatment to achieve H116 temper

Inspection and Testing

- Tensile strength testing

- Corrosion resistance verification

- Surface finish assessment

- Non-destructive testing for internal integrity

Surface Treatments

- Anodizing for enhanced corrosion resistance

- Polishing for aesthetic purposes

Huawei Aluminum: Industry Leader in Marine Aluminum Solutions

About Huawei Aluminum

Founded in 2001, Huawei Aluminum is a globally recognized manufacturer specializing in aluminum processing, with a focus on marine, transportation, aerospace, and construction sectors.

With state-of-the-art facilities and an unwavering commitment to quality, Huawei Aluminum supplies a wide range of marine-grade aluminum plates, including 5086 H116.

Why Choose Huawei Aluminum?

- Certifications & Quality Assurance: ISO 9001, CCS, DNV GL, BV certifications ensure product credibility.

- Advanced Manufacturing: Cutting-edge rolling and fabrication equipment.

- Comprehensive Product Range: Thick plates, thin sheets, custom sizes.

- Global Supply Chain: Efficient logistics and distribution networks.

- Customer-Centric Service: Technical support, customization options, reliable delivery.

Commitment to Sustainability

Huawei Aluminum emphasizes eco-friendly manufacturing processes, waste reduction, and recycling, aligning with international environmental standards.

FAQs About Marine Grade 5086 H116 Aluminum Plate

Q1: What makes 5086 H116 superior to other marine aluminum alloys?

A1: Its exceptional combination of high strength, corrosion resistance in saltwater environments, and good weldability distinguishes 5086 H116 from other alloys like 5052 or 5059.

Q2: Can 5086 H116 aluminum plates be welded easily?

A2: Yes. The alloy's excellent weldability allows for straightforward welding using common techniques, making it ideal for complex marine structures.

Q3: What are the typical thickness ranges available for 5086 H116 aluminum plates?

A3: Standard thicknesses range from 3mm to 200mm, with custom sizes available depending on project requirements.

Q4: How does the cost of 5086 H116 compare to steel?

A4: While aluminum alloys may have a higher initial material cost, their lower weight, reduction in maintenance costs, and longer service life offset the expense, often leading to overall savings.

Q5: How should I maintain 5086 H116 aluminum plates for longevity?

A5: Regular cleaning to remove salt and debris, applying protective coatings, and inspecting welds and surface integrity prolong durability.

Conclusion

Choosing the right material is crucial for ensuring the longevity, safety, and performance of marine structures. Marine grade 5086 H116 aluminum plate offers a compelling blend of strength, corrosion resistance, and ease of fabrication, making it the preferred choice for demanding marine applications.

Huawei Aluminum stands at the forefront of delivering premium quality 5086 H116 aluminum plates, backed by advanced manufacturing techniques, strict quality controls, and a customer-focused approach.

Whether you're constructing ships, offshore platforms, or specialized industrial equipment, Huawei Aluminum provides the durable, reliable materials that meet the highest standards.