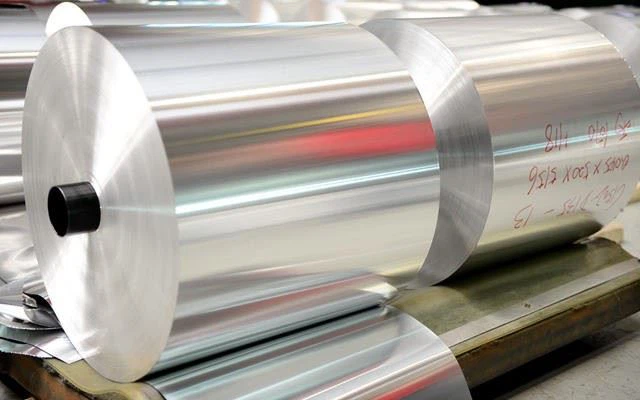

Aluminum Foil For Honeycomb Core

Width: 100–1600 mm Customizable for industrial machinery

Temper: H18/H19 Enhanced hardness and formability

Tensile Strength: 180–240 MPa Superior load-bearing capacity

Applications: Aerospace, Construction, HVAC Versatile across industries

In the world of advanced materials, aluminum foil for honeycomb core stands out as a critical component in lightweight, high-strength structures. Used across industries like construction, transportation, and aerospace, this material offers unparalleled performance and versatility. As a leading manufacturer and wholesaler, Huawei Aluminum is committed to delivering top-tier solutions that meet the evolving demands of modern engineering. In this comprehensive guide, we explore the intricacies of honeycomb core aluminum foil, its applications, and why Huawei Aluminum is your trusted partner.

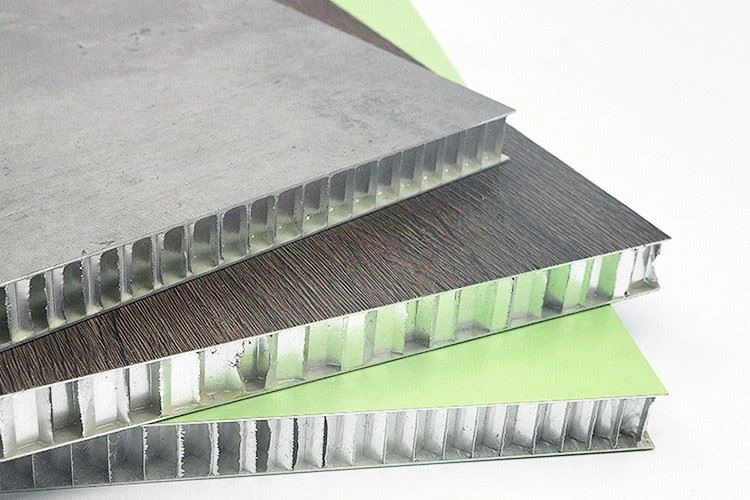

1. What is Aluminum Foil for Honeycomb Core?

The core is typically made from aluminum foil, which is bonded and laminated into a honeycomb shape. This structure resembles a series of interconnected I-beams, distributing pressure evenly and maintaining flatness over large areas.

2. Common Alloys and Their Specifications

| Alloy | Key Properties | Typical Thickness (mm) | Common Applications |

|---|---|---|---|

| 3003 | Good formability, corrosion resistance | 0.02–0.06 | General honeycomb cores, cost-effective |

| 3004 | Enhanced strength, corrosion resistance | 0.02–0.06 | Structural panels, high-performance use |

| 5052 | Superior corrosion resistance, moderate strength | 0.02–0.06 | Premium applications, marine/aviation |

- 3003 Aluminum Foil: This alloy is favored for its balance of formability and cost-effectiveness. It is suitable for standard honeycomb cores used in construction and interior design.

- 3004 Aluminum Foil: Often used in applications requiring higher strength, 3004 foil offers improved corrosion resistance and processing capabilities while maintaining affordability.

- 5052 Aluminum Foil: While more expensive, 5052 is chosen for high-end applications like marine or aerospace components, where superior corrosion resistance is critical.

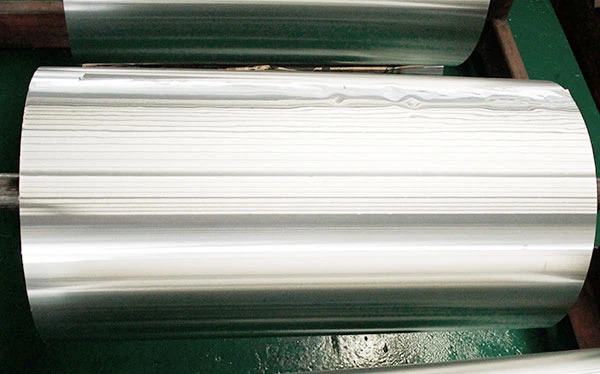

3. Manufacturing Process and Quality Control

- Degreasing: Advanced equipment and imported cleaning agents ensure the foil surface is oil-free, guaranteeing strong adhesive bonding.

- Bonding: Epoxy-modified high-temperature curing glue is used for nodes, providing ≥2.0N/mm strength to ensure structural stability.

- Quality Assurance: Real-time sheet shape monitoring and tension leveling processes ensure flatness and accuracy.

- High surface flatness

- Clean, defect-free surfaces

- Consistent cell size (5mm–12mm) for tailored mechanical properties

4. Advantages of Aluminum Honeycomb Cores

- Lightweight: Reduces overall structure weight, critical in transportation and aerospace.

- High Rigidity: Provides exceptional load-bearing capacity despite low density.

- Sound/Heat Insulation: Natural soundproofing and thermal insulation properties.

- Durability: Resistant to corrosion and environmental stress.

- Cost-Effective: 3004 and 3003 alloys offer performance at competitive prices.

5. Common Problems and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Poor adhesive bonding | Oil residue or inadequate passivation | Advanced degreasing + laser micropores |

| Uneven end faces in large rolls | Uneven winding tension | Precision tension control systems |

| Deformation during processing | Inconsistent foil thickness or poor quality | Strict quality checks + high-grade alloys |

6. Market Applications

- Construction: Curtain walls, interior partitions, and roofing.

- Transportation: Automotive collision walls, train panels, and ship cores.

- Aerospace: Lightweight aircraft components and satellite structures.

- Renewable Energy: Solar thermal back panels and wind turbine components.

- Healthcare: Cleanroom panels and medical equipment casings.

7. Why Choose Huawei Aluminum?

- Diverse Product Range: 3003, 3004, and 5052 alloys in multiple specifications.

- Advanced Technology: Cutting-edge degreasing, bonding, and quality monitoring systems.

- Customer-Centric Service: Tailored solutions and responsive support.

- Global Reach: Reliable supply chains and competitive pricing.

Send Inquiry